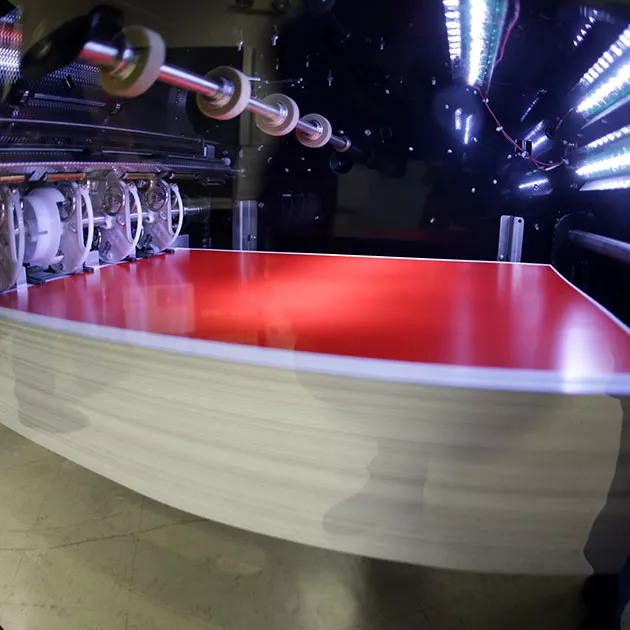

Diverse, Professional Coating & Finishing Handled In House For Maximum Savings & Quality.

From aqueous coatings, spot colors and varnishes to a vast array of cutting, trimming and finishing machinery, Raff Printing finishes projects the way they start—professionally and completely in-house.

Protecting Print Products With Multiple Coatings. Finishing Print Products With Speed & Quality.

Cutting, folding, trimming, coating – and about a dozen other “ing’s" – set Raff Printing apart as your one-stop shop for professional print production finishing. Guillotine cutters, Heidelberg Stahl folders, laminating machines, metallic inking, foil stamping, embossing… all for the purpose of creating uniquely original products.

At Raff Printing, we’ve invested time and time again in equipment that provides the latest finishes, inks and processes that set your print products apart. All while keeping costs lower and production speeds higher without sacrificing quality or service.

Learn more about binding or die-cutting here.

Coating & Finishing For Dynamic Print Materials From Raff

The added flair, extra splash of color or subtle texture of a print piece is a point of pride – and performance – at Raff Printing.

- Aqueous & UV Coating, Multiple Finishes

- Spot Varnish, Spot Color & Metallic Inks

- Laminating, Foil Stamping & Embossing

- Shrink Wrapping, Cutting & Distribution Prep

Print Coating & Finishing Customer Support FAQs

What is important to know about choosing coatings and finishes for my print project?

Printed pieces can be coated and/or finished to make a piece more durable and attractive or offer a higher-quality look or feel based on the many options available. Understanding how your print piece will be delivered, viewed, presented, and handled by the end customer helps to guide your choices.

Coatings and finishes can make an attractive brand statement and protect your print investment. The difference between the two is that “coatings” are applied as the paper is being manufactured, and finishes are applied after your piece has been printed on a particular stock. You will often hear the terms coating and finish used interchangeably.

What types of coatings and finishes are available for my project?

- Gloss, Matte & Satin Paper Coating:

Similar to what you might understand from different types of paints, these coatings vary the degree of sheen or shine of your product and can help your images pop off the page. Gloss coatings offer a highly reflective shine and are common for catalogs, magazines, and children’s books. Matte coatings diffuse or mute the look of your piece, offering a higher image contrast while being smoother than uncoated stock (paper)—think lookbooks, graphic novels and journals. Satin coatings are a happy medium between Gloss and Matte, and combine the benefits of both. - Aqueous Coating:

Standard protective clear coating which adds a slight shine to the final product while making it more durable/protected. Aqueous coating is available in gloss, matte, satin, and soft touch (see below). - UV Coating: A heavier-duty clear coating designed to protect your piece and prevent fading over time.

- Soft Touch:

One of our premium clear coats that results in a soft, velvety feel for the page that is highly tactile. - Spot Coating:

Your print piece can feature specific areas that have specific coatings or colors applied for visual emphasis, an effect that offers a satisfying feel that differs from the surrounding areas on the page(s). - Varnish:

Similar to what you might see in clear coats for wood products, varnishes are protective liquid finishes that seal in the printed ink on the surface. They are distinguished by type (varnish, lamination, etc.) and style (gloss, matte, satin, et.). and are used to protect paper from scratching, fingerprints, dirt and scuffing by increasing the resistance of the paper.

You can varnish entire pages or “spot” areas for an appealing contrast.

How much do coatings and finishes cost?

Aqueous coating has almost become a standard add-on for us, and is often included in the price of your job. As quality, enhanced feel, complexity and durability of the finished product increases, so too does the per-unit cost depending on the type of coating or finish you’ve chosen.

I’m having a tough time distinguishing between my options—do you offer samples?

Once we understand what you are looking for in your final printed piece, Raff can certainly provide samples of the types of coatings and finishes we offer that might make sense for you.